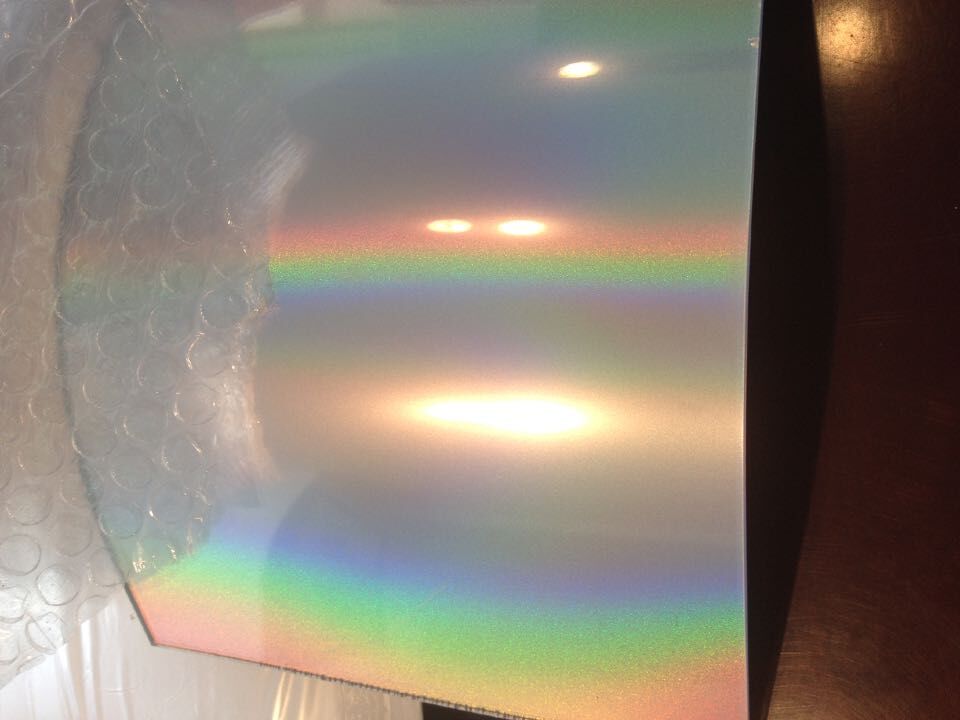

Introduction: Being an advanced light variability pigment, TRB series rainbow pigment is made through a specialized treatment process. The coated surface displays the color of metal silver under dim light and generates a rainbow effect under the direct light. Also, the surface displays different colors with the change of viewing angle.

Applications Fields:

SRB seriesrainbow pigment can be used at any smooth surfaces of base materials of surface decorations such as automobiles, home appliances, mobile phones, toys, crafts, packaging (cosmetics, liquor, cigarette packets), home decor, sports equipment (bikes, golf clubs ball head, rod), leather and wallpaper as well as various anti-counterfeiting fields. They can also be made into inks for the application of printing..

TRB series can be used at various transparent surfaces of base materials (glass, PET, PC, PMMA, PVC, etc.), surface decorations such as appliance panels, household glass sliding doors and mobile phone panels as well as various anti-counterfeiting fields.

Technical Parameters:

Appearance: gray solid slurry

SRB20: particle size D50 20μm, solid content 20%, dispersing agent 80%.

SRB35: particle size D50 35μm, solid content 20%, dispersing agent 80%.

TRB410: particle size D50 10μm, solid content 20%, dispersing agent 80%.

TRB420: particle size D50 20μm, solid content 20%, dispersing agent 80%.

TRB435: particle size D50 35μm, solid content 20%, dispersing agent 80%.

Special particle size should be processed according to user requirements.

Application Guidelines: When using the SRB20, the appearance is uniform and exquisite; when using the SRB35, the appearance is thick bright rainbow glitter. The rainbow effect is also related to resins and solvents adopted by painting. We recommend the usage of low acid value mirror resin. Make a small test before using to ensure the best results. When the surface glazing is needed, the influence of varnish on the laser layer is crucial. Because the active ingredient of SRB is aluminum, you must use a low acid value varnish (acid value <5). Furthermore, the dissolving power of varnish should be moderate. If the dissolving power is much too strong, the surface of base material or laser layer may dissolve, which destroys the ordered arrangement of SRB, leading to a substantial decrease of laser effects. Recommended Dosage The dosage of SRB in paint is recommended to be among 0.5-2% of the amount. The dosage of ink should refer to the amount of TRB series.

This product is a non-leafing pigment. We recommend that the formulated inks should be printed on the back of the transparent base materials. The base materials which are smooth and transparent can generate the best rainbow effect. Rainbow effect is related to the pigment particle size. When using the size of 10μm, the appearance is uniform and exquisite; when using the size of 35μm, the appearance is thick bright rainbow glitter. The effect of 20μm size is situated between the above two ones. The rainbow effect is also related to resins and solvents adopted by inks. We recommend the usage of low acid value mirror resin. Make a small test before using to ensure the best effects. Recommended Dosage (silk screen inks) The dosage of TRB in inks is recommended to be among 10-20% of the amount. The smaller particle size uses more dosage while the bigger particle size uses less dosage.

As follows: 10μm pulp 16-20%, resin and solvent 80-84%, screen mesh 300 mesh

20μm pulp 14-18%, resin and solvent 82-86%, screen mesh 250 mesh

35μm pulp 10-14%, resin and solvent 86-90%, silk screen of 200 mesh

Safe storage: It should be stored at the temperature between 10 ℃ -25 ℃ in drying room, keeping the container sealed, with storage period of six months.

Package: 100 g, 200 g, and 500 g.