HUE liquid crystal material

HUE has advanced liquid crystal material formulation technology and high-quality liquid crystal coating formula products, which can be supplied in batches and high-quality. The comprehensive use of HUE liquid crystal materials can manufacture a variety of special optical devices and optical films, and are widely used in displays and decorations. , Anti-counterfeiting and other fields. The market is gradually developed and expanded to more potential applications, such as spiral phase retardation film, anti-blue light film, non-absorption circular polarizer, DBEF brightness enhancement film, coated polarizer, liquid crystal waveguide film, liquid crystal decorative film, liquid crystal anti-counterfeiting Film, anti-counterfeiting ink, discoloration car jacket, etc.

HUE polymerizable liquid crystal material has the advantages of easy orientation, high solubility, easy adjustment of the liquid crystal phase interval, selectable birefringence, and excellent physical and chemical resistance after film formation. It can provide professional liquid crystal formula in combination with application conditions to improve product quality and yield. The combination of polymerizable liquid crystals can achieve the following key parameter ranges:

Liquid crystal phase interval: 50℃-130℃

Birefringence: 0.1 – 0.21

Wavelength dispersion type: positive dispersion or reverse dispersion

Stable concentration (cyclohexanone@25℃): 20%-55%

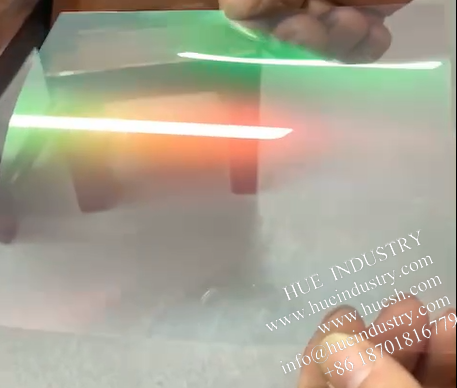

HUE LCD Ink

HUE liquid crystal ink shows different colors after coated at different angles, and the color range can be customized. After film formation, it has high light transmittance, and the light transmittance can reach more than 95%. Compared with the conventional pigment system coating, the liquid crystal ink forms a film has no graininess, strong metal reflectivity, and remarkable discoloration effect. It is mainly applied through processes such as UV system spraying and rolling.

Precautions for laboratory coating process

1. Coating environment

Temperature: 20-24℃

Relative humidity: 50-60

Cleanliness: not less than ten thousand

2. Coating process requirements

1. Wear dust-free gloves for the experiment operation, and use a clean glass straw to suck the formula solution;

2. Use 19-50um PET as the substrate to avoid fingers touching the coated surface of the substrate;

3. Choose a wet coating amount of about 10-12g/m2 (usually the laboratory uses No. 2 wire rod)

4. The temperature of the blast oven is 90℃, 2 minutes.

5. UV curing energy 500-800mJ/cm2. If the power of the high-pressure mercury lamp is too low, the coating surface may not be cured sufficiently. It is recommended that the curing process be carried out in an inert atmosphere (such as a nitrogen atmosphere).

6. Equipment cleaning solvent type: ketone solvent